SWLA Drone Services LLC

24/7 Drone Operations

SWLA Drone Services offers continuous aerial coverage and rapid-response capability, enabling ranchers and farmers to monitor assets, inspect infrastructure, and gather critical data at any hour; by combining night-capable sensors, automated flight planning, and trained remote pilots, around-the-clock drone programs reduce downtime, improve situational awareness, and accelerate decision-making while maintaining safety and regulatory compliance through rigorous maintenance, contingency procedures, and real-time oversight. SWLA Drone Services also offers traditional video and photography packages.

VIDEO and PHOTOGRAPHY

Basic photography services are $100 an hour with a 2 hour minimum.

Basic video services are $100 an hour with a 2 hour minimum.

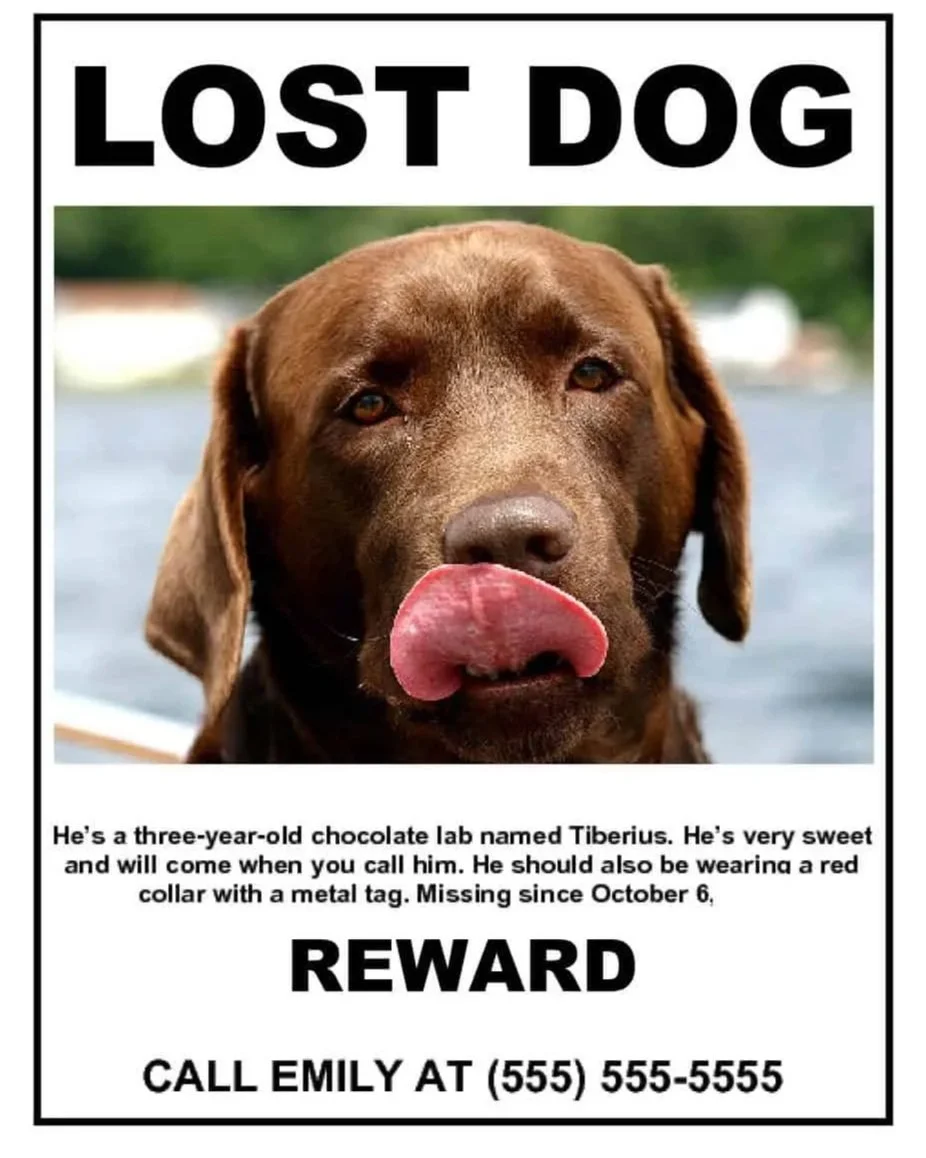

SWLA Drone Services LLC is on call 24 hours a day 7 days a week for lost pet search and rescue. We use the newest drone thermal and visible light cameras to find your lost pet day or night.

Lost pet callout is $300 due at time of call. Callout price includes 3 hours onsite. A $100 finder’s fee is due if pet is found. Additional travel fees below.

Drive fees

0-45 minutes - free

45-90 minutes - $100

90-120 minutes - $175

Contact Jason at (337)540-6278

Our Services

24/7 LOST PET SEARCH AND RESCUE

CATTLE HERD HEADCOUNT

Basic Herd Count

A basic herd headcount will consist of a basic report of the cattle in the designated area. The generated report will show the total headcount in the designated area. All photos and video taken will be included with the report.

Advanced Herd Count

An advanced herd headcount will consist of a detailed report of the cattle in the designated area. The report will show the total headcount divided into bulls, steers, cows and calves. All photos and video taken will be included with the report.

Available on 24/7 callout for emergency situations.

Contact Jason for a free consultation (337)540-6278

FENCE LINE INSPECTION

A fence line inspection will consist of multi-angled video of the designated length. A report will be generated documenting any deficiencies with an 8K resolution photograph and centimeter accurate waypoint. All photos and video taken will be included with the report.

Available on 24/7 callout for emergency situations.

Contact Jason for a free consultation (337)540-6278

WILDLIFE HEADCOUNT

Wildlife Headcount

A wildlife headcount would consist of a basic headcount of the wildlife in a designated area. The generated report will show the total headcount in the designated area. All photos and video taken will be included with the report.

Available at extra cost

Individual pictures of all animals in 8K resolution.

Contact Jason for a free consultation (337)540-6278

LEVEE INSPECTION

A levee inspection will consist of multi-angled video of the designated levees. A report will be generated documenting any deficiencies with an 8K resolution photograph and centimeter accurate waypoint. All photos and video taken will be included with the report.

Available on 24/7 callout for emergency situations.

Contact Jason for a free consultation (337)540-6278

DRONE REPAIR

At SWLA Drone Services we also offer drone body repair using 3D printing.

Overview 3D printing (additive manufacturing) has become an essential tool for drone repair and maintenance. It enables rapid, cost-effective replacement parts, custom upgrades, and on-demand fabrication that reduce downtime and extend vehicle life. For commercial operators, service providers, and hobbyists, integrating 3D printing into repair workflows improves turnaround, reduces inventory costs, and allows design optimizations not feasible with traditional manufacturing.

Common Use Cases

Broken propeller guards, landing gear legs, and motor mounts: Frequently damaged, these parts are ideal for 3D printing due to simple geometry and the ability to print strong, lightweight replacements.

Custom mounting brackets and sensor housings: Tailor-fit parts for payloads (cameras, LiDAR, RTK modules) can be printed to match drone frames precisely.

Structural reinforcements and repairs: Cracked arms or frame sections can be replaced or reinforced with printed sleeves, clamps, or full arm replacements.

Jigs, tools, and fixtures: Custom repair jigs, test stands, and service tools can be printed quickly for shop efficiency.

Prototype improvements and iterative upgrades: Rapidly test new designs for improved aerodynamics, cable management, or cooling before committing to production parts.

Materials and Their Uses

PLA: Easy to print and dimensionally stable. Suitable for non-structural components, housings, and jigs. Low heat resistance—avoid near motors or batteries.

PETG: Good balance of strength, flexibility, and chemical resistance. Common choice for removable clips, guards, and moderately stressed parts.

ABS: Higher impact resistance and temperature tolerance. Suitable for structural parts but requires heated enclosure for reliable prints.

Nylon: Excellent toughness and abrasion resistance for high-wear components (gears, hinges). More demanding to print.

Carbon-fiber–filled filaments (PLA/PETG/Nylon blends): Increased stiffness and strength for load-bearing parts like motor mounts and arms. Note: abrasive to nozzles—use hardened tooling.

Design Considerations

Load paths and orientation: Design parts to align printed layers with principal loads where possible. Print orientation strongly affects strength.

Infill, wall thickness, and raster orientation: Increase perimeters and select higher infill for structural parts; use solid walls for connection points and threads.

Fillet and chamfer transitions: Reduce stress risers at joins and mounting interfaces to improve fatigue life.

Fastener strategy: Use embedded nuts, captive inserts, or metal reinforcements at high-load attachment points rather than relying solely on printed threads.

Tolerances and fit: Account for filament shrinkage and printer accuracy. Provide clearance for snap fits or press-fit pins.

Heat and UV exposure: For parts near motors or battery bays, choose materials with appropriate heat deflection temperature; add UV-resistant coating or use UV-stable filament for outdoor exposure.

Let’s Work Together

If you're interested in working with us, complete the form with a few details about your project. We'll review your message and get back to you within 48 hours.